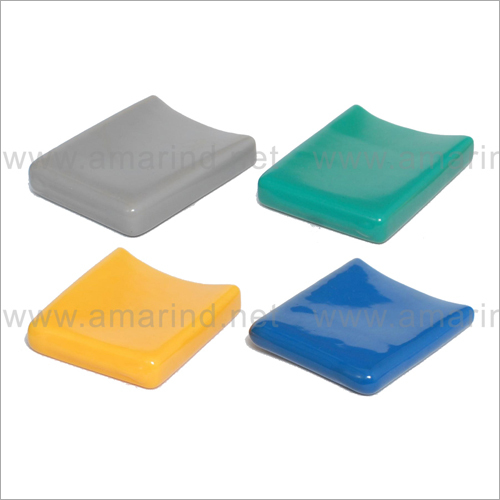

Dip Molded Cable End caps

Product Details:

- Thickness 0.8 mm - 2 mm (approximate)

- Cable Diameter 4 mm to 40 mm (available in various sizes)

- Sealed Yes (moisture and dust resistant)

- Surface Treatment Smooth

- Product Type Dip Molded Cable End Cap

- Material PVC (Polyvinyl Chloride)

- Application Electrical cable insulation and end protection

- Click to View more

Dip Molded Cable End caps Price And Quantity

- 10 Piece

- 500.00 - 1000.00 INR/Piece

Dip Molded Cable End caps Product Specifications

- High (typical for PVC/rubber)

- Round End Cap

- As per size selection (multiple sizes available)

- 0.8 mm - 2 mm (approximate)

- 4 mm to 40 mm (available in various sizes)

- Black

- Very low (as per PVC characteristics)

- Electrical cable insulation and end protection

- Up to 600V (typical for cable end caps; depends on material and thickness)

- Smooth

- PVC (Polyvinyl Chloride)

- Yes (moisture and dust resistant)

- Dip Molded Cable End Cap

- Not applicable (no terminal socket)

- Lightweight (varies by size)

- Slip-on, tight fit over cable end

Dip Molded Cable End caps Trade Information

- 100 Piece Per Week

- 5 Days

Product Description

DIP Molded Cable End Caps

A DIP Molded Cable End Caps are strong & permanent environmental seal. They have excellent resistance to weather, moisture contamination & adverse environmental conditions. They are a low-cost solution for a variety of user applications as protectors for tubing, threaded parts, and as covers for bolts and screws. These offered caps are manufactured from high quality raw material and advanced technology with the support of skilled professionals. The DIP Molded Cable End Caps are very efficient and safe for use

Product Details

Available in full range for busbar | 20x3 mm to 120x10 mm |

Brand | AMAR |

Material | Compounded PVC |

Cable diameter | 5.5 mm to 120 mm |

Reliable Insulation & Safety

Designed for efficiency, these end caps create a secure barrier over cable ends to prevent dust, moisture, and accidental contact. The high insulation resistance and tight fit ensure protection for electrical connections up to 600V, while their smooth finish simplifies installation and removal. Their construction enhances safety for both indoor and outdoor applications.

Versatile Sizes & Applications

Available in multiple sizes to accommodate cable diameters from 4 mm to 40 mm, these round PVC caps suit various electrical, power, and AV setups. Dealers and manufacturers can conveniently select the right fit for their specific needs, whether for industrial machinery or home wiring systems. Lightweight and pliable, they adapt easily to most cable types.

FAQs of Dip Molded Cable End caps:

Q: How should I select the correct size of dip molded cable end cap for my cable?

A: To select the appropriate size, measure the outer diameter of your cable and choose an end cap size that matches or is slightly smaller to ensure a tight, slip-on fit over the cable end. Sizes are available from 4 mm to 40 mm in diameter.Q: What are the key benefits of using these cable end caps for electrical insulation?

A: These cable end caps offer high insulation resistance, help prevent short circuits, seal against moisture and dust, and enhance cable lifespan. Their tight fit also minimizes contact resistance, providing reliable protection up to 600V (depending on material and thickness).Q: Where can these PVC cable end caps be used effectively?

A: They are ideal for applications in power distribution, electrical wiring, audio/video systems, and industrial machinery, suitable for dealers, exporters, and manufacturers across India requiring durable cable end protection.Q: What is the process for installing these cable end caps?

A: Simply slide the round end cap over the stripped or exposed cable end until it fits tightly. The flexible PVC allows for easy installation and removal, and the reusable design enables multiple usage cycles without loss of fit.Q: Are flame retardant and UV resistant versions available for outdoor or specialized use?

A: Yes, flame retardant and UV resistant variants can be provided upon request, making them suitable for outdoor or harsh environment applications where additional protection is required.Q: When should I replace or reuse the cable end cap?

A: You can reuse the end caps as long as they maintain a snug fit and are free from visible damage. Replace them if you notice cracks, significant wear, or if the cap no longer seals properly against moisture and dust.Q: What compliance and resistance features do these end caps have?

A: Our cable end caps are RoHS compliant, exhibit high insulation resistance typical of PVC or rubber, maintain low contact resistance, and are resistant to moisture, dust, and optional UV exposure, making them a safe and reliable choice.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

AMAR INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |