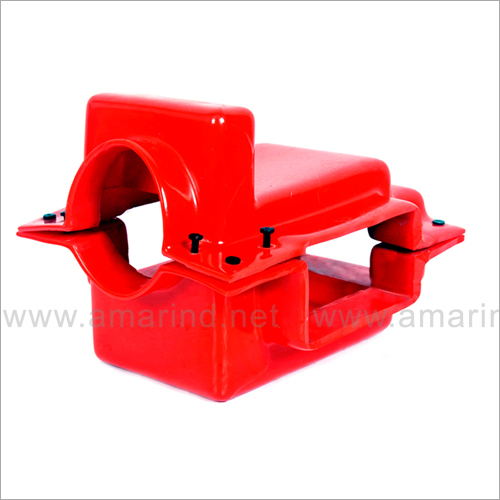

Bus Bar Joint Shrouds and Boots

Product Details:

- Cable Diameter Suitable for bus bar up to 45 mm width

- Surface Treatment Smooth, anti-corrosive finish

- Thickness 2.5 mm average

- Sealed Yes, fully encloses bus bar joint

- Product Type Joint Shroud & Boot

- Material High-grade PVC/Polymeric insulated material

- Application Electrical power distribution panels

- Click to View more

Bus Bar Joint Shrouds and Boots Price And Quantity

- 10 Piece

- 500.00 - 1000.00 INR/Piece

- Rectangular for shroud, cylindrical for boots

- >30 kV/mm

- -20°C to +70°C continuous

- RoHS & IEC60439 Compliant

- Tool-free, manual fitting

- UL94-V0 classified

- Waterproof and dustproof

- UV Stabilized for outdoor use

- Up to 1.2kV AC/DC

- Standard: 15mm, 25mm, 32mm, 45mm widths

Bus Bar Joint Shrouds and Boots Product Specifications

- Standard bus bar mounting

- Suitable for bus bar up to 45 mm width

- Joint Shroud & Boot

- Approx. 60 grams per shroud

- Red, Yellow, Blue, Black, Green

- Snap-fit and slip-on types

- Electrical power distribution panels

- <0.01

- Joint Shroud / Boot

- Up to 1000 V AC/DC

- Covers diameter up to 38 mm (boot type)

- 2.5 mm average

- >1000 M at 500V

- Smooth, anti-corrosive finish

- High-grade PVC/Polymeric insulated material

- Yes, fully encloses bus bar joint

- Rectangular for shroud, cylindrical for boots

- >30 kV/mm

- -20°C to +70°C continuous

- RoHS & IEC60439 Compliant

- Tool-free, manual fitting

- UL94-V0 classified

- Waterproof and dustproof

- UV Stabilized for outdoor use

- Up to 1.2kV AC/DC

- Standard: 15mm, 25mm, 32mm, 45mm widths

Bus Bar Joint Shrouds and Boots Trade Information

- 100 Piece Per Week

- 5 Days

Product Description

Bus Bar Shroud Joints and Boots

Bus Bar Shroud Joints and Boots is a light weight and compact connecting and insulating device which is used to connect two bus bar at the corner. It is manufactured by using especially formulated poly vinyl chloride which makes it highly resistant to the impacts of electrical shocks, moisture, water and chemical attacks. It is designed with high precision by using latest production techniques which gives smoother finish and high dimensional accuracy for better fitting.

Product Details

Properties | Value | Standard |

|---|---|---|

Physical | ||

Tensile Strength | 11 N/mm² (MPA)(min.) | ASTM D 412-06a |

Ultimate Elongation | 250% (Min.) | ASTM D 412-06a |

Longitudinal Change | 0.5 % (Max.) | ASTM D2671 |

Hardness | 60 ± 10 Shore D | ASTM D2240 |

Water Absorption | 0.5 % (max.) | ASTM D570 |

Thermal | ||

Accelerated Ageing for 110°C for 300 Hrs | ||

Tensile Strength | 9 N/mm2 (Mpa) (min.) | ASTM D 412-06a |

Ultimate Elongation | 150 % (Min.) | ASTM D 412-06a |

Heat Shock (120oC for 4 Hrs.) | No Cracking or flowing | ESI 09-11 |

Continuous Temperature limit | -40°C to + 110°C | IEC 216 |

Electrical | ||

Dielectric Strength | 6 to 12 KV/mm. | ASTM D149 |

Volume Resistivity | 1012 Ohm.cm | ASTM D257 |

Flammability | ||

Flammability | Pass | UL-94 (V-0) |

Superior Electrical Insulation

With a dielectric strength above 30 kV/mm and insulation resistance greater than 1000 M at 500V, these shrouds and boots offer outstanding electrical protection. They minimize the risk of electrical faults, making them ideal for high-voltage environments in industrial and commercial applications.

Effortless, Tool-Free Installation

Specially engineered for manual fitting, these shrouds and boots utilize snap-fit and slip-on styles for easy installation and removal. No specialized tools or expertise are required, streamlining the process for technicians and ensuring secure fitting around bus bar joints.

Rugged Performance in All Conditions

The waterproof, dustproof, and anti-corrosive design offers superior resilience against harsh weather and environmental challenges. Coupled with full UV stabilization, these shrouds and boots maintain integrity and color over prolonged outdoor exposure, supporting reliability in demanding settings.

FAQs of Bus Bar Joint Shrouds and Boots:

Q: How are Bus Bar Joint Shrouds and Boots installed without tools?

A: These protective covers feature snap-fit and slip-on mechanisms, allowing for easy, tool-free installation by hand. Technicians can securely fit them around the bus bar joints without specialized equipment.Q: What benefits do the flame retardancy and UV resistance provide when using these products outdoors?

A: Flame retardancy (UL94-V0) increases safety by minimizing fire risk, while UV stabilization safeguards material integrity and color, ensuring durability and performance for outdoor electrical installations.Q: When should I use different sizes and colors of bus bar shrouds and boots?

A: Select sizes based on the bus bars width (15mm, 25mm, 32mm, 45mm) and colors to mark phases or circuits for clear identification, enhancing safety and organization within your power distribution panel.Q: Where are these joint shrouds and boots typically applied?

A: They are used in electrical power distribution panels to fully enclose bus bar joints, providing insulation and protection in installations ranging from substations to industrial plants throughout India.Q: What process ensures these products safety and regulatory compliance?

A: Manufactured using high-grade PVC/polymeric material, each piece is tested to meet RoHS and IEC60439 standards for electrical safety, insulation resistance, and environmental responsibility, ensuring reliable and certified protection.Q: How does the waterproof and sealed design benefit bus bar installations?

A: The fully sealed structure prevents water, dust, and contaminants from entering, reducing corrosion and enhancing the longevity and operational safety of electrical connections in indoor and outdoor environments.Q: What is the maximum operating voltage supported?

A: These shrouds and boots safely enclose bus bar joints with operating voltages up to 1.2kV AC/DC, and are rated up to 1000V AC/DC, supporting a wide range of medium-voltage electrical applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

AMAR INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |